The 43rd edition of MCE – Mostra Convegno Expocomfort closed its doors at Fiera Milano last March with a bunch of proposals on the road to efficiency, sustainability and innovation. Under the claim of ‘Beyond Comfort’, Mostra gathered the biggest companies in the HVAC+R, renewable energy, energy efficiency and water world.

Our international Knauf Industrial Solutions team joined the meeting to put into value our existent solutions for the sector. But, most of all, to share our expertise with smart costumers to work together, hand in hand, towards more efficient systems.

Sustainability and EPBD4 Directive: what comes next?

The edition was focused on energy efficiency and energy transition with the new EPBD4 Directive as a framework. The European Parliament definitively approved the text only a few days before Mostra, including a new ‘A0’ class in the APEs (Energy Performance Certificates), corresponding to ZEmBs.

The Directive also encourages the use of all adaptive technologies to ensure the proper functioning of buildings and maximum efficiency in all climatic conditions. “One of the major challenges for HVAC market is the increasing requirements for all market actors to be aligned with the sustainability rules and, at the same time, increasing the HVAC devices efficiency. In this regard modern materials and lighter components with EPP can be a solution”, declares Agnieszska Ludwiniak, Marketing Director for Knauf Industries Poland.

Considering that the days are numbered for gas boilers in Europe, “we can speak about an exponential growth of heat pump solutions”, remarks Mrs Ludwiniak.

Energy efficiency and comfort

The urgent decarbonisation demands more efficient buildings. It involves a better thermal insulation, but also more efficient HVAC systems from the beginning to the end of life. Mostra gave the chance to show new solutions.

“Around 90% of current HVAC equipment is made of sheets, metals, and inefficient materials. EPP improves insulation, simplifies the assembly process, it lightens the weight of the product… These are advantages for both the manufacturer and the end user”, explains Jordi Iglesias, Industrial Solutions International Business Development Manager. “In fact, our material insulates and prevents noise and vibrations. Therefore, it contributes to comfort at home”.

Michel Rives, HVAC Product Manager, rehearses some critical points shown at Mostra where little changes mean a huge improvement in energy efficiency:

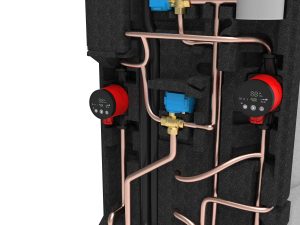

- Airtightness in ventilation units with heat recovery and heat pumps. “The design requires sometimes several parts to obtain the set and all of them need strong mechanical connection without any air leak”. Obviously, the more components, the more difficult to keep it.

- Easy & safe maintenance. The plug for maintenance (e.g. filter access) should be easily removable without degrading the airtightness.

- Airflow under control. “For air/water heat pump, the evaporator airflow has a direct impact on the appliance efficiency. It’s important to create an airtight channel between the fans and the coil to concentrate it where it is needed”.

Innovation: combining metal and foam alliance

Foam components, and especially EPP, can make old metal mechanisms lighter, simpler and more efficient. “EPP is a disruptive solution which allows to achieve real improvement in the appliance efficiency, compared to classic way to design appliances (sheet metal). The key point is to integrate this material or solution directly at the beginning of the project to take advantage of this asset”, says Michel Rives.

Some manufacturers may be reluctant to a material they see lightweight, cheap, or even, fragile. “Sure, compared to sheet metal the mechanical features are intrinsically lower than foam but perfectly adapted for HVAC market. For example, the thickness of sheet metal is systematically decreased to the minimum for economic and weight reasons. On top of that it’s not so easy to add functionalities without adding components, insulation, components support, wire fixation, etc…. On this point, adding foam components is the perfect solution”, explains Rives.

In this transition to old and new materials symbiosis, manufacturers need to have a suitable partner with real know-how and the ability to innovate. “Throughout the last 10 years, at KNAUF we have developed several outstanding solutions and projects being a real partner in supporting clients in HVAC appliance designing. What is more, we offered advanced engineering and innovation with our R&D center”.

What manufactures want: more competitivity saving time and money

Every minute counts, and so does every extra gram. Visitors at Mostra demanded HVAC systems to be efficient, but also easy to assemble and disassemble to repair. And as light as possible to be easy to load, install and manipulate (even with less occupational risk). Knauf Industrial Solutions in EPS and EPP come to help both manufacturers and installers.

“Our EPP components are composed of 95% air and the EPS ones are even 98% air. This means EPS & EPP technical parts for HVAC devices are really lightweight and hence so easy to transport and assemble even by one person. That applies even to large-size components, like HRU casings or heat pump and boiler insulation”, declares Mrs Ludwiniak. “This means valuable economies in labor cost to our OEM clients in HVAC sector”.

Our engineers have also designed and developed special joining techniques for certain parts. This turns into effortlessly click-join components where they needed to be glued before. Moreover, our experts help device producers to design customized assembling systems of our foam components which make the device assembly fast and easy.

Jordi Iglesias remarks that “manufacturers achieve a lower overall manufacturing cost, since they can reduce the number of materials and suppliers, reduce stock, machinery… And let’s not forget that an innovation in the product revalues it in the market”.

As a conclusion for the four intense days at Mostra, our team have seen an increasing interest in product design and aesthetics. Here’s where all alternative options that bring a differential design (plus efficiency, of course) are welcome.