Knauf Industries

Expertise

Knauf Group

Expertise

We are renowned experts in the expanded foam moulding industry with more than 30 years of experience combined with high-technology production installations, an international presence and excellent financial strength. As a major player in injection moulding, Knauf Industries offers its industrial customers all over the world a unique combination of several know-how in plastic moulding technologies.

Our research and development installations, design offices and technical sales team are fully skilled in offering a wide range of plastic-based solutions.

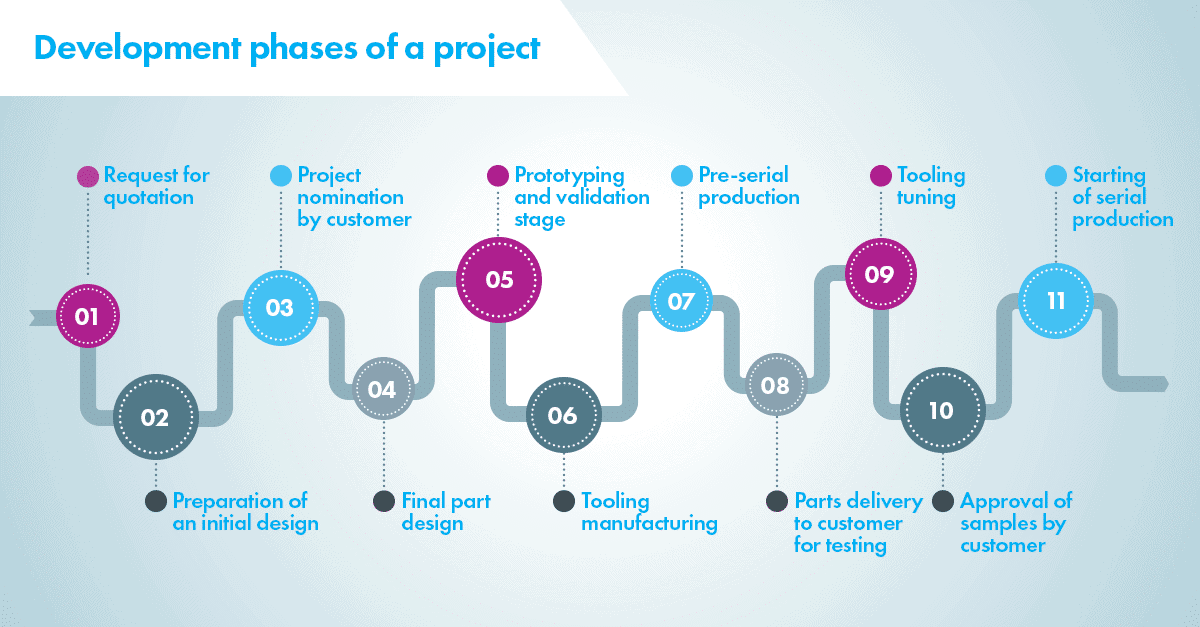

Project management

Quality Certification Systems

Knauf Industries is recognised worldwide for its ability to develop turnkey projects for its clients, from the design of a part or packaging to the construction of a production plant dedicated to the client. And then describe shortly each phase of the project development:

You can also describe that we perform 3 cooperation models with our customers:

–Support in design + tooling coordination + serial production.

–Design delivered by client, and we step in the tooling phase and later on perform the manufacturing of the parts.

–The last model, where we can take over a tool ready for production and perform the process.

Technologies

Plastic Technologies

Injection technology

Technologies

We are specialists in thermoplastic injection technology and decorative plastic parts for various industries. Our know-how also extends to gas injection technology, aesthetics and electronic moulding. Our exterior and interior injection moulded components for the HVAC industry are mainly manufactured from the following materials: – polystyrene (PS), – polypropylene (PP), – ABS, – PC, – PC / ABS, – PC / PMMA. In order to guarantee the aesthetic appeal of the components, we use various decorative techniques: water painting, two-colour painting, masking, pad printing, entry, hot stamping.

Moulding technologies

Expanded Polypropylene (EPP) / Expanded Polystyrene (EPS) processing

Plastics moulding technology has been a Knauf Industries core business ever since its creation. Our expertise is in EPP and EPS moulding. Our 41 EPP/EPS processing plants are strategically located to best serve the supply chains of our most demanding international clients.

The industrial expertise, moulding know-how, and market experience are crucial for solutions development of foam products on the HVACR market. Our teams work closely with clients to evaluate their needs and define technical requirements for expanded foam products that meet their expectations. After a thorough analysis and fluid communication with the client, we work on custom-designed foam solutions or design to cost-effective solutions, ensuring through our recommendations a suitable material choice and clear specifications for meeting both the quality and functional goals in the manufacturing of the parts.

Materials

With our processing equipment, we are able to process a variety of foam materials as well as all known co-polymers.

We manufacture our houselhold appliances packaging and components using a variety of expanded foam materials including expanded polypropylene (EPP) and expanded polystyrene (EPS) and other special co-polymers. For the production of injection molded HVACR components we efficiently process: PC, PS, ABS, PC/ABS and many more.

Expanded Polypropylene (EPP)

Expanded Polypropylene (EPP) is a trustworthy and well-tested material used in a wide variety of industrial applications.

Thanks to its lightweight, structural, thermal and acoustic insulation properties, EPP helps to increase performance and reduce the cost of manufacturing equipment in the HVACR sector. Expanded polypropylene can be manufactured in a wide range of densities, from 15 to 250 g/l.

The highly versatile closed-cell bead foam thus obtained offers a unique range of additional properties, which are widely used by industrial manufacturers:

- Light weight

- Acoustical absorption

- Airtightness

- Thermal insulation

- Buoyancy

- Water and chemical resistance

- Exceptionally high strength to weight ratio

- 100% recyclability

Combined with other components and materials, EPP is successfully used in technical parts to combine strength and lightness and thus optimize manufacturing costs.

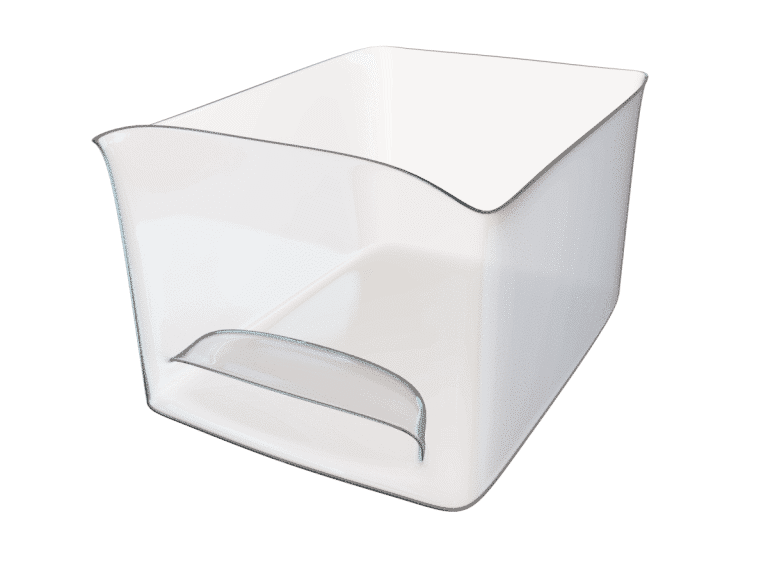

Our offering of Expanded Polypropylene components comprises:

- Ventilation box

- Insulation of hot water tanks

- Thermodynamic component support

In addition, the EPP is the perfect material solution for revolving packaging, which protects fragile parts during transport and storage.

Expanded Polystyrene (EPS)

Expanded polystyrene is a cellular material widely used in the industrial world. EPS is produced by expanding polystyrene beads with a steam process. The balls are transformed into fine spherical particles composed of 98% air and 2% polystyrene. The material can be processed by moulding into packaging and components of various shapes and sizes.

As experts in lightweight and durable foams, we manufacture a wide variety of cost-effective expanded polystyrene packaging and protection solutions for our HVACR and household appliances customers.

The material boasts a great number of properties that make it a privileged alternative to other plastics:

- Expanded Polystyrene is 98% air, 2% polystyrene

- wide range of densities, from 8 to 150 grams per litre

- exceptionally light and flexible, yet durable

- EPS is safe and environmentally neutral

- excellent insulating and acoustic properties

- 100% recyclability

Quality

Quality Certification Systems

Our 42 manufacturing facilities are certified by a number of different bodies relating to Environment, Quality Management, and Health & Safety. By obtaining and maintaining these industry leading certifications, we can guarantee our clients that our products and processes are in full compliance with international and national regulations and standards.

ISO 9001-Quality Management Systems

What are the advantages of ISO 9001 for our clients?

The ISO 9001 is a guarantee for the continuous improvement of quality management systems (QMS) and processes in all our production sites. Owing to our certification we are able to meet the most rigorous quality requirements of our customers by following the 7 principles:

– QMP 1 – Client centric: Our primary focus is to meet client requirements and to strive to exceed their expectations.

– QMP 2 – Leadership: Our leaders at all levels establish unity of purpose and direction to create conditions in which people are engaged in achieving the quality objectives of the organization.

– QMP 3 – Engagement: Our co-workers at all levels across the organization are competent, empowered and engaged people focused on creating and delivering value.

– QMP 4 – Process approach: Our business activities are understood and managed as interrelated processes that function as a coherent system. This approach delivers consistent and predictable results ever effective and efficient.

– QMP 5 – Improvement: We focus on the improvement of process performance by means of root-cause investigation and determination followed by prevention and corrective actions. ISO 9001 guarantees the ability to anticipate and react to internal and external risks and opportunities. It also encourages the drive for innovation throughout the organization.

– QMP 6 – Evidence-based decision making: we understand perfectly the cause-and-effect relationships and potential unintended consequences in our business activities. Facts, evidence and data analysis lead us to greater objectivity and confidence in decision making.

– QMP 7 – Relationship management: Optimal relationship management with our supplier and partner networks is of outmost importance for us. It ensures a well-managed supply chain that translates into a stable flow of goods and services, and increases the capability to create value for all stakeholders, by sharing resources and competences.

ISO 14001-Environmental Management Systems

What are the benefits of ISO 14001 for our clients?

– Constant compliance with environmental legislation

– Minimisation of energy and resource usage reducing operating costs

– Constant improvement in environmental performance