Injection molding technology

Plastic injection molding is one of the key plastic processing technologies used by Knauf Industries. The possibilities for its application are vast and we can fully customize any project. At the Knauf Industries Group sites – we specialize in the supply of plastic products from the following materials PS, PP, ABS, PC, PC/ABS, PC/PMMA, PA, PP/EPDM, PA6 GF30, PP GF30 and PP+T as well as foamed plastics molding.

Why choose Knauf Industries as supplier of plastic injection molded parts?

Plastic injection molding is a proven technology used in industrial manufacturing that provides tremendous opportunities. By using our technology, companies in many industries can enter a whole new level in terms of quality, production efficiency and usability. Entrust your project into the hands of specialists.

Put your project in the hands of specialists.

We have more than 20 years’ experience in providing innovative solutions to a variety of industries such as white goods, HVAC, as well as the world’s largest automotive original equipment manufacturers, among others.

- We operate according to a one-stop-shop concept successfully combining multiple processing technologies and additional processes. Within this framework, we offer professional technological support and efficient process implementation.

- Thousands of customers have placed their trust in us, all thanks to our compliance with the highest quality standards for our products and services.

- We build added value for the customer comprehensively. We also provide an individual approach – each project is preceded by a feasibility study.

- We work with more than 30 different injection mold manufacturers with factories all over the world, and our customers can choose between tool shops in Europe and Asia.

We are a supplier with a solid background that helps minimize risk. Behind the Knauf Industries plants is the capital potential of the Knauf Group, enabling investment and rapid innovation for the smooth implementation of even the most demanding injection molding projects.

What is injection molding technology?

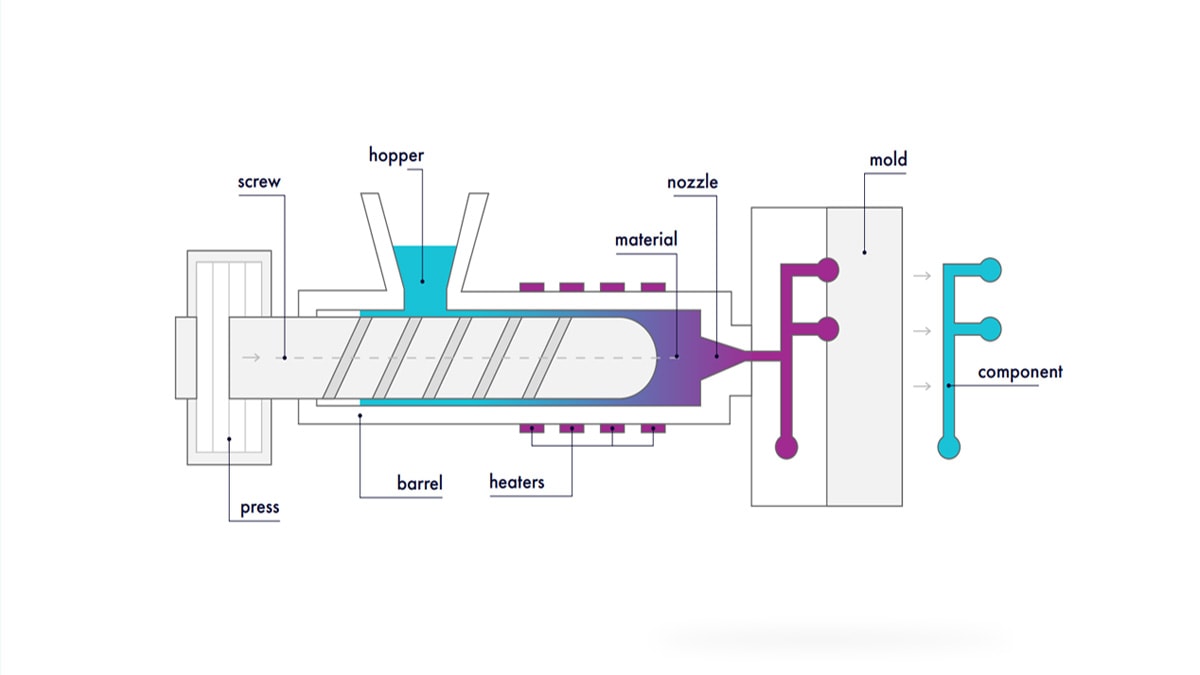

Injection molding is one of the most established technologies for producing plastic components. It is a process in which plastic granulate is melted and then injected under pressure into a special mold. The prepared material then hardens, resulting in a product – so-called molded part – with a defined shape and parameters.

At Knauf Industries, we ensure the highest quality of service delivery and manufacturing process

We guarantee the support of our engineering team and a comprehensive approach to the production of plastic parts. We offer professional technological advice and efficient implementation of the injection molding process.

Full engineering and design support

Our qualified team of engineers not only takes care of the production process itself, but also handles pre- and post-process services.

As part of our plastic injection molding services, we comprehensively handle all phases of production – from simple manual operations to complex, multi-stage automated processes.

- We prepare the feasibility study of the part

- We manage the development of injection molding tools

- We carry out plastic processing

- We provide quality control of the final injection molded component

- We offer pre-assembly and post-processing services: application of tapes and clips, assembly of modules

- We deliver the final product fully compliant with the customer’s expectations

Full engineering and design support

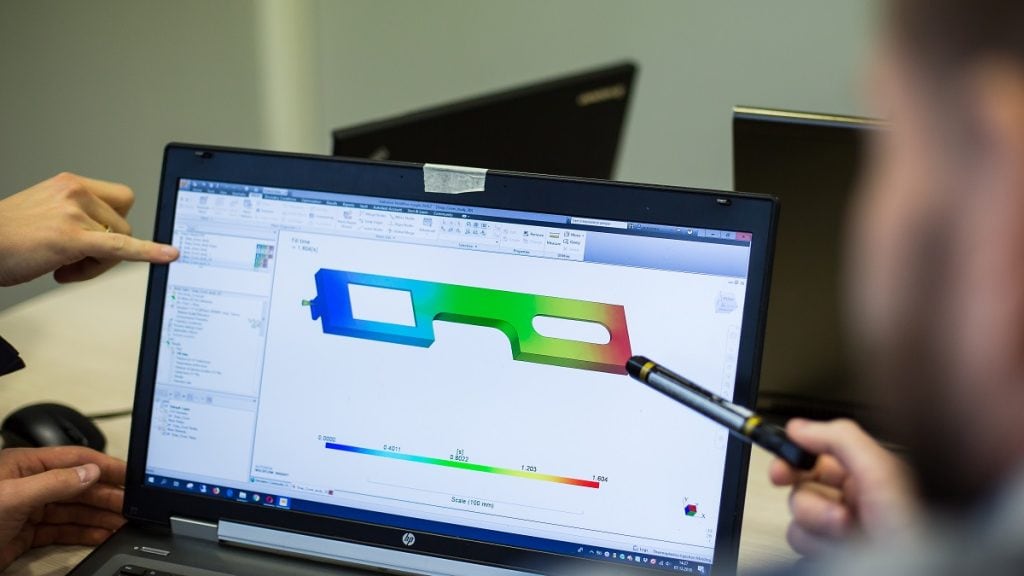

Every step of the manufacturing process, from concept to final product, is meticulously managed by our experienced engineers. We offer optimal injection molding solutions and conduct advanced simulations to improve the product. As a result, parts are produced with the highest precision, efficiency and cost-effectiveness.

Post-production services after the injection molding process

In addition to the injection molding process, the post-production services that Knauf Industries offers to all its customers are also important, guaranteeing faster lead times and a shorter supply chain. These include:

- component assembly

- ultrasonic welding

- production and processing of plastic parts

- quality control

- packaging

- preparation of parts for dispatch.

One stop shop. More than standard

Thanks to over 20 years of experience, a modern technology park and the implementation of additional services in the one-stop-shop concept, we ensure the highest quality of services and production of injected components.

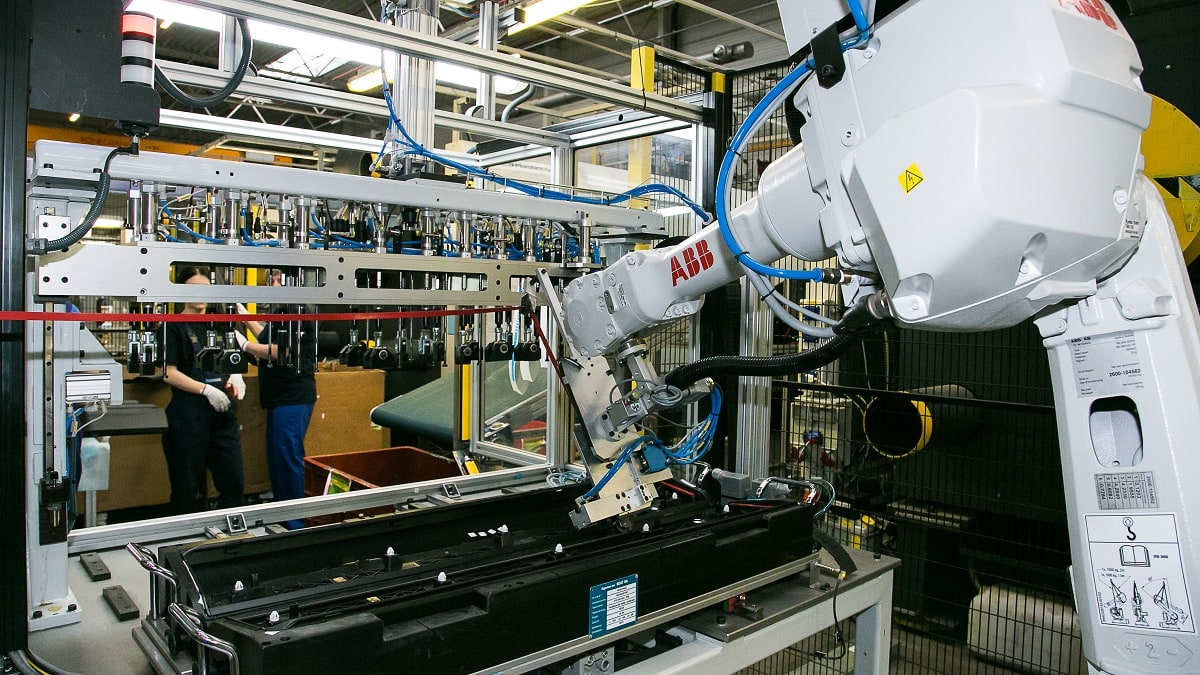

A modern production facility Knauf Industries plastic parts are made in our production plant in Wrocław (Nowa Wieś Wrocławska). The base of the injection molding machine park is a set of modern machines, including over 20 injection molding machines, with a clamping force from 80 T to as much as 2000 T. Presses equipped with SEPRO manipulators are additionally supported by 6-axis ABB robots that perfectly cope with more complex operations such as e.g. cutting of injected parts, gradation and flame cutting.

High quality and reliability of plastic injection confirmed by certificates

The quality of our plastic products is confirmed by numerous certificates, including IATF 16949 (quality system in the automotive industry) and ISO 9001:2009. We adhere to high production standards, offering our customers top-shelf solutions. All processes and products comply with local and global regulations. At every stage of production, we also focus on taking care of the environment and applying the principles of sustainable development. We are committed to reducing the impact of our operations on the natural environment as much as possible, which is why our plants implement an energy-saving strategy and meet the highest environmental protection standards.