We all want to feel at home. This means achieving adequate thermal comfort and maximum soundproofing for noise from mechanical equipment that allows you to maintain a comfortable temperature. Insulating foams are our greatest allies in achieving this.

But we are not the only ones to benefit. The energy and environmental impact of an HVAC (heating, ventilating and air conditioning) system that loses heating or cooling potential is enormous.

Making progress with suitable structural insulation for buildings allows you to reduce our energy bills. But it is of no use if the ventilation or air conditioning devices (heat pumps and air conditioners) have poor energy efficiency.

Using the right insulation materials allows for proper, more efficient and quieter running. All that can be summed up in one word: comfort.

Types of expanding foam insulation and their uses

Although they have similar names, expansive foams and expandable (or expanded) foams refer to several materials with different uses and performance.

Expanding foam insulation is sprayed or injected into a space in liquid form. In a matter of seconds it expands to fill the space, creating an effective insulation barrier.

These injectable foams include polyurethane (PU) expanding foam. It can be applied locally to home insulation to seal air leaks through cracks.

In addition to injectable foams, there are other forms of building insulation using expanding foams.

Expandable foams are insulating materials that are applied locally, and are pre-moulded with the aim of preventing thermal bridges. These same expanding foams, such as expanded polystyrene (EPS) and expanded polypropylene (EPP), also provide optimal insulation in HVAC equipment.

Insulation with expanding foam provides, among other benefits, thermal insulation, energy savings, leak tightness and soundproofing.

The two mono-materials have low thermal conductivity, are highly resistant to moisture, and do not allow the growth of micro-organisms. The last two properties, as you will see, are essential in environments prone to localised moisture condensation, such as HVAC systems.

In addition, both EPS and EPP are extremely lightweight materials (96-98% air). This reduces the weight of the equipment, making it easier to handle and install.

As they are mouldable, they can be customised for a millimetre-perfect fit for housings and other technical parts. This fine-tuning will ensure maximum airtightness; in other words, no air leakage at any joint.

Air sealing and soundproofing with expanded foam insulation

The interior of your home (or office) should be as close to a safe refuge as possible. A place where you can concentrate in order to work, rest, feel at ease with your loved ones, and protect yourself from the hustle and bustle of the outside world.

None of this is possible if, on a sweltering hot day, the air conditioning ‘doesn’t cut it’. Or if, when running, it generates an exasperating engine noise that leaves you wondering whether it is better to put up with the heat or not sleep due to the incessant rumblings of the appliance.

The use of expanded foams in HVAC equipment provides airtightness and sound insulation. This allows you to achieve and maintain the desired temperature, but without the inconvenience of noise.

Leak tightness

HVAC systems contain a gas that varies in temperature depending on the pressure. This gas flows through ducts, where it either dissipates its heat or transmits cold. In this way, it modifies the temperature of the air in the room that you wish to cool or heat.

If the circuit is not well-sealed, air or other fluids may leak.

In purely economic and comfort terms, this is a point of energy inefficiency. From an environmental perspective, it means increasing the carbon footprint linked to the running of our equipment.

This fault is easy to detect: it happens when you connect your equipment for heating or cooling and, despite turning it up to full power, you don’t notice a perceptible change in temperature. Or you do, but at the cost of a significant increase in energy bills.

To prevent fluid leakage, metal clamps and fasteners are usually fitted. But the more elements that are incorporated within a circuit, the more vulnerable to leakage it becomes.

EPP and EPS foams allow the custom-made moulding of insulating parts for the entire structure. They are fitted using pressure, without fasteners, avoiding the creation of thermal bridges. In the specific case of EPP, their elastic recovery properties are exploited to cover the entire space.

As such, you end up with a single piece that fits the shape of the circuit and provides an excellent seal.

Soundproofing

HVAC systems are pieces of mechanical equipment made up of various parts, through which fluids circulate under varying pressures. Although in recent years technology has succeeded in reducing vibrations, some noise is unavoidable.

Such equipment is designed to operate several hours a day, or continuously, as in the case of ventilation systems. Needless to say, putting up with constant humming can be annoying, irritating or a nightmare for users. Worse still, it can trigger conflicts with neighbours.

We are not talking about a small nuisance for noise-sensitive people. How many times have you had to turn off the air conditioning in a hotel room because the noise has kept you awake at night? A noisy appliance can cause stress, insomnia, headaches, and make it difficult to concentrate.

Expandable EPP and EPS foams consist of small air-filled airtight cells. This characteristic makes them an excellent barrier against sound transmission and a damper against vibrations.

Therefore, in addition to preventing air leakage, they mitigate noise generated when the equipment is running.

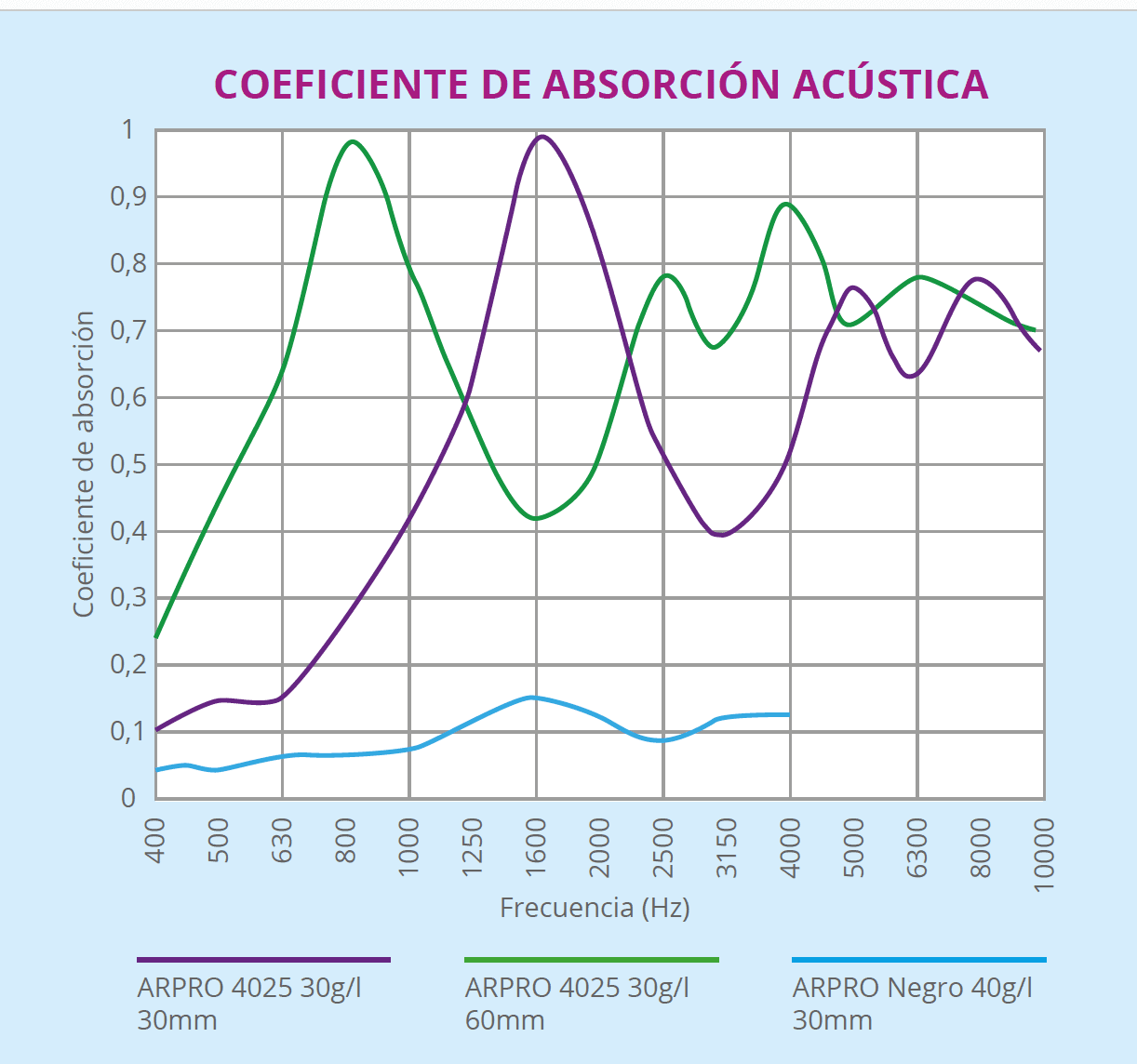

Specifically, there is a porous EPP with improved sound insulation properties. It is very effective for a frequency range between 600 and 10,000 Hz.

Thermal insulation and energy savings with expanding foams

Over time, these factors become a guarantee of comfort, health and longevity for your home. Not to mention the ‘health’ you will be giving to your family finances by avoiding overpaying on the energy bills to keep your home comfortable.

Structure with expanded foams

Manufacturers and consumers are increasingly demanding HVAC systems. Efficient simplicity is one of its requirements. The other is aesthetics. Both can be achieved with tailor-made components in EPP.

A single EPP part can be moulded to replace many other small components. It can even provide structure to the system, making it unnecessary to install a metal plate to attach to the wall.

Because it is so versatile and offers the possibility to be manufactured in different colours, textures, qualities and shapes, it is now possible to mould aesthetically pleasing components to be visible, without the need to hide them under an additional casing. At Knauf Appliances we have developed a palette with 36 textures in 4 different lines following the latest trends in industrial design.

Durability of equipment with expanded foam insulation

HVAC systems have two major enemies that affect their durability: vibrations and humidity.

In the first case, constant movement causes friction between the parts and results in premature wear.

Moisture appears where there is air leakage due to condensation. This can also happen if the water in the circuit leaks out. It is important to bear in mind that these systems are traditionally made using metal parts, which are very vulnerable to rust. Over time, rusted areas may start to malfunction.

Localised humidity also favours the appearance of moulds and fungi, both in the system itself and on adjacent walls or ceilings. This problem may just be aesthetic and easy to repair, or it can become a health risk factor for the users of the building.

Both EPP and EPS have a high vibration damping capacity and a high resistance to moisture. They are naturally water-repellent and inert. In other words, they prevent the proliferation of micro-organisms on their surfaces, even under favourable conditions regarding heat and humidity.

Properly insulating our HVAC equipment with expanding foams reduces the risk of in-use breakdowns. In short, it extends the useful life of your appliances and gives you the peace of mind of knowing that you will be comfortable.

Knauf Appliances solutions that improve insulation using expanded foams

At Knauf Appliances we are experts in designing and manufacturing customised insulation solutions with maximum leak tightness, using expandable foams for HVAC systems. Thanks to these components, your HVAC equipment will provide optimum performance and your users will enjoy maximum comfort.

– – – – – – – –

FREQUENTLY ASKED QUESTIONS ABOUT EXPANDING FOAM INSULATION