Shock Absorption & Protection

How does a shock absorber work?

Let’s start from the beginning: what is a shock? A shock is the effect of an impact force on an object over a short time period. The effect occurs when the energy of the impact is transferred from one individual or object to another and can be damaging for some elements or the complete receptor object.

With the goal of reducing or mitigating these adverse consequences, shock absorbers come into play. Thanks to a process called damping, they promote the dispersion or disruption of the energy caused by impact forces by decreasing its strength or amplitude or by changing the energy wave’s frequency.

In the automotive industry, among others, these mechanical or hydraulic devices are designed to absorb and damp shock impulses by converting the kinetic energy of the shock into another form of energy (normally heat) that is dissipated.

Why is shock absorption important?

Shocks can occur anywhere and are usually associated with negative effects to objects or individuals that will cause damage or inefficiencies. Think for example of a track full of fragile load or a vehicle driving on rough ground. In both situations they are affected by different types of shocks and some degree of protection is needed to guarantee the integrity of the goods or the correct functioning of the motor, respectively.

Therefore, it is no wonder that shock absorption plays a major role, as it is necessary to help increase the lifespan and the safe operation of items and applications.

Also in mechanical systems unwanted mechanical energy can manifest itself as a vibration or noise, causing damages to the delicate content. Choosing the right shock absorbing materials in the design phase can be decisive for electronic components.

Types of shock absorption materials

There are various types of shock absorbent materials available depending on various factors such as the applications and the object to be protected.

Concrete:

It is the most rigid material to protect against crashes but non-flexible at all. This means that after a great impact it will become useless

Metal

it has less rigidity but is relatively flexible. Nonetheless, it is not flexible enough to recover its original shape and be able to resist another impact. In practice, it does not resist such great impacts and does not recover its shape either.

Polymers

they combine a high flexibility with good resistance levels that vary according to its composition. Any polymer barrier has a specific ability to take an impact, bend, resist energy, and return to its original shape. This means that even if all polymers are not the same, they all have the basic properties to be good shock absorbers. Protection foams are specially noteworthy.

To sum up, when choosing an absorption material it is essential to consider a variety of factors such as the rigidity and flexibility of the material, the coupling between pieces or the type of protection. That will guarantee an optimal protection.

What are the most important characteristics of a shock absorption material?

Besides the above mentioned resistance and flexibility, shock absorbing materials need to meet some requirements in order to be optimal for protection. Particularly, they are meant to:

What are the most important characteristics of a shock absorption material?

Besides the above mentioned resistance and flexibility, shock absorbing materials need to meet some requirements in order to be optimal for protection. Particularly, they are meant to:

- Present a high degree of shock and energy vibration absorption.

- Perform in both low (≈ –30°C) and high (≈ 70°C) temperatures.

- Perform at frequencies ranging from 10 to 30,000 Hertz.

- Have an optimal damping ratio.

- Not support bacterial or fungal growth.

- Be chemically unaffected by industrial solvents such as diesel fuel, kerosene and hydraulic fluid.

- Have a long shelf life.

- Have a superior damping coefficient.

Our shock absorption and protection products

At Knauf Industries we have long been a well-known player in the market for designing industrial production of plastic technical and protective items.

EPP and EPS are two prominent foam shock absorbers as well as our strategic materials. Aside from its high resistance to impact, they are light, chemical resistant, good thermal insulators, waterproof and 100% recyclable. Also, they are so versatile that they allow customization and freedom of design. That explains why they are perfect to create all kinds of protection packaging.

Among our solutions, we can highlight four main areas where the foam shock absorption protection is vital:

Electronics

Due to its high resistance to impact, compression and temperature and also thanks to being waterproofing, EPP material is perfect to protect delicate electronic components which must stay away from water or sudden temperature changes. It is also a great alternative to substitute wires, clips or metal boards, as it holds components in place while keeping them protected from impact.

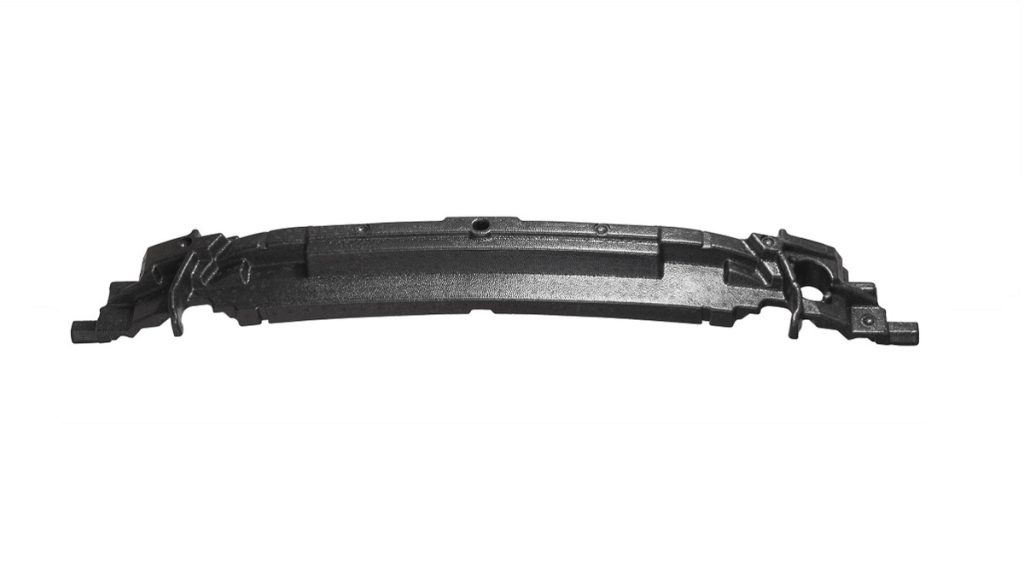

Automotive

The high impact absorption of EPP coupled with its mechanical resistance make it a suitable material for certain passive safety elements in vehicles. This is why it is used in seats, boot compartments, or mat cushions, among others. It is even used in car seats for children and to protect car batteries.

Pharmaceutical

Maintaining the cold chain is vital when transporting pharmaceutical products in order not to spoil them. In this regard, isothermal containers made with EPS are a great alternative for thermolabile medicaments among others.

EPS also stands out in terms of hygienics, as it prevents the growth of microorganisms. In this way, they protect the products inside against processes such as decomposition and guarantee that they arrive in perfect safety conditions.

Agri-food

the most appreciated characteristics here, apart from protection to shocks and vibrations, are isothermality, UV resistance and non-toxicity. Thanks to our EPP products food is well preserved and is properly protected during transport without the need for refrigeration.

All of this allows us to predict that impact absorbing foams are the future of the industry. Such is their reputation that the value of the protective foam market values is expected to grow at a compound rate of 6.3% from now to 2028.