Acoustic Insulation

What is acoustic insulation?

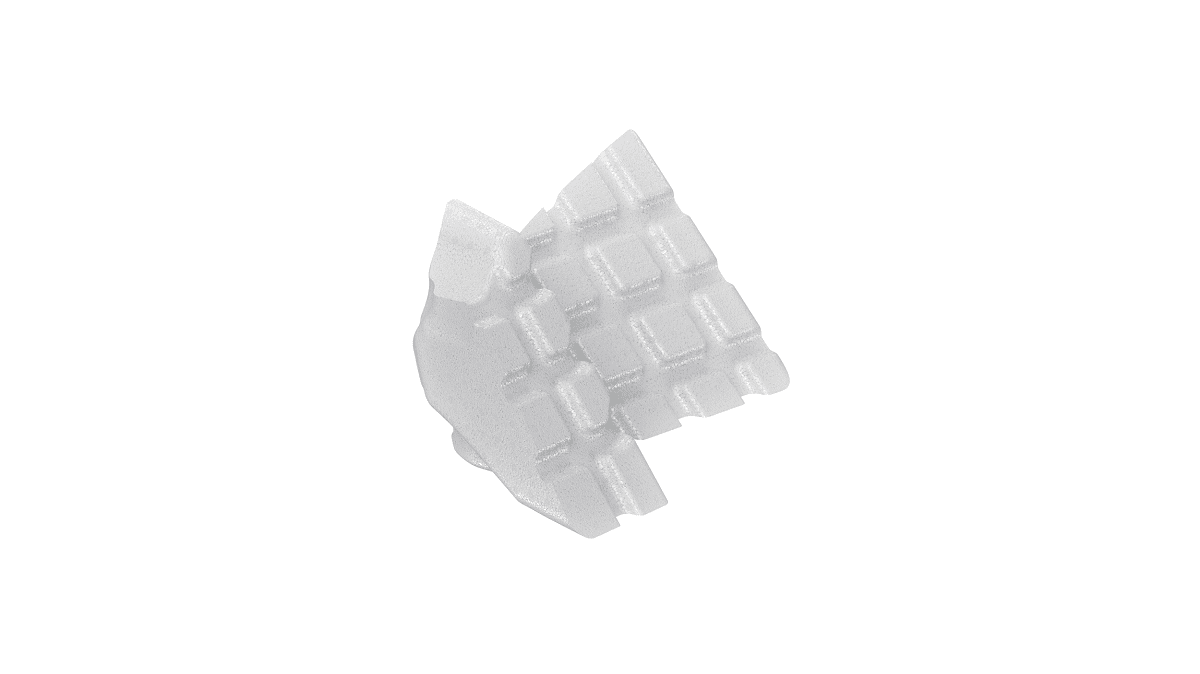

Acoustic insulation consists in reducing noise from a source and its consequent transference to the recipient. This is achieved by creating some kind of barrier between them, usually thanks to closed-cell materials with void spaces that are responsible for absorbing sound waves. Bearing this in mind it is no wonder that materials such as EPP (Expanded Polypropylene) and EPS (Expanded

-Polystyrene) are such excellent acoustic insulators.

There are certain fields where soundproofing plays a central role, for example, construction, industrial products, HVAC systems or home appliances. This is because the use of their own machinery can provoke annoying noises that must be dampened in order to guarantee comfort.

How does acoustic insulation work?

Acoustic insulation consists in adding mass to help stop noise from passing easily through a structure. It is also used to reduce the amount of reverb and echo, which is a secondary effect of acoustic contamination.

In this regard, it is essential to choose the right materials, as some are better than others at blocking different types of sound. As stated previously, materials such as EPP and EPS are ideal for this purpose, as they not only have advanced acoustic insulation properties, but also high strength to weight ratio, impact resistance and flexibility, which are useful characteristics.

Zooming in on how EPP is capable of absorbing sound in such a way, the answer should be found in its cell structure. The perforated EPP enhances the sound absorption behavior, as sound and vibrations get trapped within the air voids thanks to this cell structure.

If we take for instance the case of industrial parts or HVAC systems, acoustic insulation works by creating household receptacles and industrial components in EPP or EPS aimed at reducing the nuisances generated by pumps, valves and control mechanisms. In turn, due to its lightweight nature, using these materials to acoustically insulate these items represents a significant improvement to earlier heavier structures.

What are the benefits of acoustic insulation?

The most relevant benefit from soundproofing has to do with human health. In this regard, the World Health Organization (WHO) has issued multiple noise standards for buildings and industries, resulting in the study of impacts of ambient noise on the health of people. In this field, for example, acoustic insulation helps create a safe environment preventing hearing loss, disrupting sleep or a reduction in productivity levels, among other problems.

Not only this, it also has some other benefits that should not be ignored: it improves comfort and privacy in buildings, industries and even vehicles; avoids annoyance from sounds in adjacent properties, such as footsteps or music; and increases the value of the properties, as it has long-term advantages that are valuable for buyers.

This explains why the global acoustic insulation market size is expected to reach $21,205.7 million by 2030 (which means a CAGR of 5.6% from 2021 to 2030).

EPP for acoustic insulation

Due to perfect acoustic absorption, thermal insulation, durability, low weight and high elasticity, EPP is the ideal alternative for metal, wood and hard plastics in a broad range of solutions.

Performance of expanded polypropylene

Expanded Polypropylene is a 95% air closed-cell material that features air pockets within the hollow cylinder-shaped particle structure which enhance acoustic performance and act as a great sound barrier to prevent sound waves transmission. What is more, there is a porous EPP that improves said property, being very effective for a range of frequencies between 600 and 10000Hz.

Use cases of EPP

HVACR systems

It allows obtaining enlarged three-dimensional shapes, active hinges, inserts and cable ducts. Housings made with EPP allow for easy maintenance, thanks to simple assembly and an organized structure and drastically reduce the acoustic nuisances of the functioning machinery.

Home appliances

Customers are becoming more and more sensitive to the noise generated by home appliances. That is the reason why manufacturers of dishwashers, washing machines or laundry dryers, among others are increasingly considering the reduction of the acoustic nuisances to create brand identity and even a competitive advantage.

EPS for acoustic insulation

Due to its multiple properties, Expanded Polystyrene is an outstanding material, as it is an excellent thermal and thermo-acoustic insulator, it offers high compressive strength properties, it is shock-absorbent, water-repellent, lightweight, suitable for food contact, stable, and retains all its properties over time.

Performance of expanded polystyrene

EPS is a highly versatile closed-cell bead foam widely used in the industrial world. It is produced by expanding polystyrene beads with a steam process, which transforms them into fine spherical particles composed of 98% air and only 2% polystyrene material. Due to its characteristics it can go a step further than the vast majority of other types of materials, especially in terms of acoustic insulation.

In order to maximize its acoustic insulation properties it has to be elasticized, becoming EEPS (Elasticized Expanded Polystyrene). EEPS is designed to compress when the pressure is on and expand back again when the pressure is released. These material sheets are characterized for having a smooth surface, a straight edge, low dynamic rigidity and low thermal conductivity and to efficiently interrupt the transmission of sound and impact thanks to the separation that they achieve from the flooring and the slab. Most precisely, its low dynamic rigidity achieves levels of acoustic insulation of SD20 (17.5 MN/m3).

Use cases

EPS acoustic insulation properties make it an extremely used material in construction. It is also a frequently used material in the automotive industry, HVACR systems and home appliances. Let’s have a quick look at its main use cases:

Insulation systems:

The insulation of buildings is made with EPS and not with EPP, due to its better suitability for use. Precisely, EPS is the most widely used insulating material for ETICS systems (Exterior Thermal Insulation System) , since it is a solution that provides an unbeatable value for money, responding to the technical requirements of these systems in all types of weather. These SATE systems are used to thermally and acoustically insulate a façade from the outside, presenting great advantages from the point of view of energy saving, environmental impact and comfort. This explains why it is widely used both in new construction and rehabilitation of buildings.

Motor vehicle interior components

Due to its impact resistance, shock absorption capability, sturdiness and soundproofing, EPS is an excellent alternative to use in vehicle interiors to create comfort while guaranteeing protection.

HVACR systems:

By making EPS housings the noise of the functioning machinery is drastically reduced.